- Coffee Packaging Bags

- Baby Food Packaging Bags

- Tea Packaging Bags

- Frozen Food Packaging Bags

- Protein Powder Packaging Bags

- Spice Packaging Bags

- Rice Packaging Bags

What are you looking for?

Aluminum foil film is a plastic film that is coated with a very thin layer of aluminum. The aluminum is melted and evaporated at high temperature under high vacuum conditions, and the aluminum vapor is deposited on the surface of the plastic film. It has the characteristics of both plastic film and metal, and is a cheap, beautiful, high-performance packaging material.

The most common material is VMPET and VMCPP.

The barrier layer excels in moisture resistance, dust prevention, shock absorption, and odor control, effectively safeguarding the packaged products from external environmental factors, thereby preserving their freshness and quality.

Cast polypropylene (CPP) is a polypropylene film produced by flow-molding in the plastics industry.It's a non-stretched and non-oriented cast film

Oriented Polypropylene (OPP) is only stretched on TD direction

Biaxially Oriented Polypropylene (BOPP) is stretched both on TD direction and MD direction

Monoaxially Oriented Polypropylene(MOPP) is only stretched on MD direction

Bags of different capacities have different sizes, usually measured by weight and volume.

1 Pound (LB) = 453 Grams

1 KG = 2.2 LB

1 OZ = 29.57 ML

Cromalin Proofs result from a specific proofing method designed to authorize offset CMYK printing prior to the actual press run.

Developed by duPont, Cromalin is both a brand name and a unique process.

These proofs serve as press proofs to finalize design approval in the printing workflow.

Following this, the next phase is the press check. Created by pre-press experts at the printing facility, Cromalin proofs are one of several proof types utilized in the industry.

CMYK (cyan, magenta, yellow and key-black) is a color process used in printing, especially for photorealistic images and images with multiple colors. These inks are semi-transparent and mixed together to produce a range of colors.

Compostable plastic bags can be degraded by naturally conditions and are ultimately completely degraded into carbon dioxide (CO2) and/or methane (CH4), water (H2O) etc.

Child resistant bags feature a two-handed locking system and secured zipper to prevent children from opening.

Density of common plastic film roll:

| Common materials | Density/gram weight |

| OPP | 0.91 |

| CPP | 0.91 |

| VMCPP | 0.91 |

| PE | 0.93 |

| PA | 1.14 |

| PET | 1.4 |

| VMPET | 1.4 |

| AL | 2.6 |

| Kraft Paper | 50 |

| PLA | 1.28 |

Digital printing is the direct conversion of electronic files into printed products without the need for traditional printing plates, the advantage of digital print is low MOQ and fast lead time.

Environmentally friendly packaging bags are categorized into recyclable packaging bags and biodegradable packaging bags.

The flat bottom bag, also known as the eight-side seal bag, is a type of laminated packaging bag named for its distinctive design featuring eight sealing edges—four at the bottom and two on each side. It has a flat base.

Flexible packaging bags refer to containers whose shape can change when the contents are filled or removed. We can provide laminated plastic packaging bags.

FDA (Food and Drug Administration) is a test standard of materials safety that can come into contact with food is directly related to the food safety and health of users.

Gravure printing is to cover the entire surface of the printing plate with ink, and then use a special scraper to remove the ink from the blank part, so that the ink remains only in the cells of the image part, and then transfer the ink to the surface of the film under greater pressure.

Gravure printing uses a large amount of ink, the images and texts have a convex feel, rich layers, clear lines and high quality.

A gusset refers to the bottom or side panels in flexible packaging bags, such as stand-up pouches or flat-bottom bags. Its presence increases the bag's volume and provides additional space for packaging design.

Kraft paper weight and thickness Conversion:

| GSM | Thickness |

| 28 GSM | 0.04mm |

| 40 GSM | 0.06mm |

| 50 GSM | 0.06mm |

| 60 GSM | 0.07mm |

| 70 GSM | 0.08mm |

| 80 GSM | 0.11mm |

| 80 GSM | 0.10mm |

| 100 GSM | 0.12mm |

| 120 GSM | 0.13mm |

| 120 GSM | 0.14mm |

A process that combine two or more layers of film materials into one through a lamination machine

Advantages of laminated film

a. Combine the advantages of multi-layer materials;

b. Protect the ink from falling off;

c. Prevent the ink from contacting the contents.

MD (Machine Direction) is the longitudinal direction of the film

TD (Transverse Direction) is the transverse direction of the film

It is achieved by printing a special matt oil ink on the bag to eliminate the glossy effect on the surface.

MVTR (Moisture Vapor Transmission Rate)

The lower the value, the better the moisture resistance

NY ( Nylon ) has excellent tensile and puncture resistance, Because of its puncture resistance, it is often used for packaging vacuum and sharp-cornered items.

low temperature and high temperature resistance, and the operating temperature range is -60℃~225℃, so it can be used as a printing material for packaging frozen products and high-temperature steamed products.

PE (polyethylene), the main types are low-density LDPE, medium-density MDPE, high-density HDPE, and linear low-density LLDPE.

PP (polypropylene) is the lightest resin among all plastics and has the lowest density.

① High transparency;

② Good printing performance;

③ Higher mechanical strength than PE, that is, not easy to stretch, especially the performance of biaxial stretching is relatively low;

④ Good moisture resistance, often used as the surface layer of biscuits;

⑤ Good acid, alkali and oil resistance, such as oil packaging and the inner heat sealing layer usually use CPP instead of PE;

⑥ General gas barrier performance;

⑦ Better high temperature resistance than PE, worse than PET and NY;

The function of the printing plate is to print the graphic information on the original on the printing plate, and transfer it to the film through the printing machine and special ink to achieve batch reproduction of the original content.

During the printing process, the graphic part on the printing plate accepts ink, while the non-graphic part forms a blank and does not accept printing ink.

PET ( polyethylene terephthalate ) is suitable for printing materials of various products. It is a widely used printing material and cannot be used as a heat-sealing layer material.

PET is good transparency, resistance to low and high temperatures, melting point of 264°C, not easy to wrinkle when sealing, good flatness, especially suitable for automatic packaging machines.

Polylactic acid (PLA) is one of the biodegradable plastics. Its raw materials come from renewable plant fibers, corn, agricultural by-products, etc., and it has good biodegradability.

PLA has excellent mechanical properties, similar to polypropylene plastics, and can replace PP and PET plastics.

PLA can be decomposed into water, carbon dioxide, and methane by microorganisms existing in nature.

Pull Tab Zipper allows the contents of the bag to be loaded from behind the zipper, avoiding contamination and extending the service life of the zipper.

RGB stands for Red, Green, Blue and is the color model for computer screens, televisions, smartphones, and more.

Packaging bags made of a single material are recyclable.

Laminated pouches in multi-material cannot be seperated so they are not recyclable.

We offered PE/PE or PP/PP rececable packagimg bags.

Retortable pouch is a special packaging bag, usually used for packaging food, which can be cooked at high temperature.

A process that slit one film roll into Slitting specified sizes by slitting machine.

Spot UV refers to glossy on the key information while other places are matt finish.

By alternating between glossy and matte, the packaging bag has unique artistic and visual effects.

The spout bag is a new packaging for beverage, liquid and bulk solid packaging products.

It is widely used in the packaging of liquids, sauces, pastes, powders, beverages and detergents

It can be filled manually or automatically at the top of the bag or at the spout.

They are also safer and cheaper to transport than glass bottles.

A stand up pouch is a type of flexible packaging bag with a horizontal support structure at the bottom, allowing it to stand upright without any external support. This relatively novel packaging format offers several advantages, including enhancing product quality, improving shelf visual appeal, being lightweight and easy to carry, convenient to use, and providing freshness and resealability.

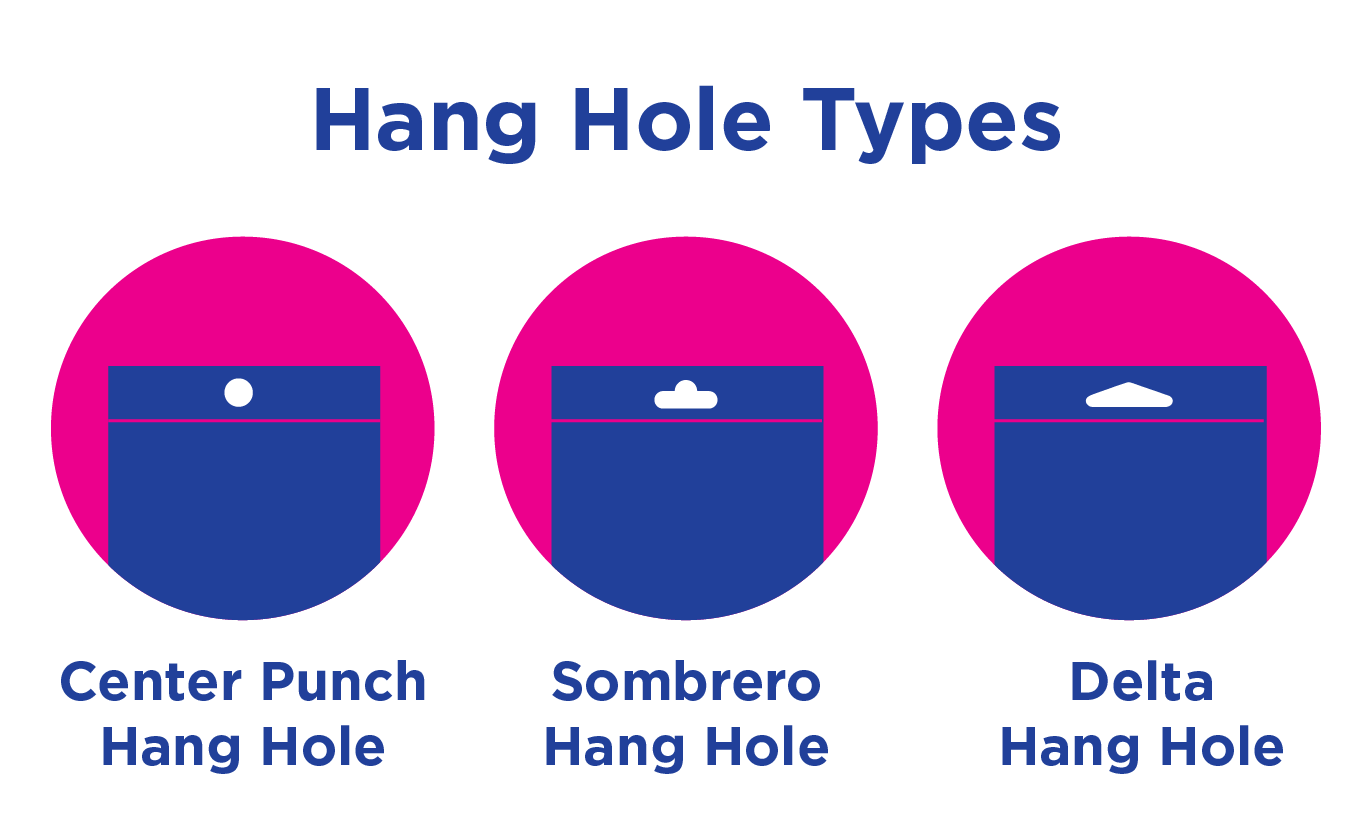

Sombrero Hang Hole refers to the hanging hole shaped like a brimmed hat

Spot color is not synthesized by printing the four colors C, M, Y, and K, but is printed with a specific ink.

Food packaging bag Shelf Life is between 6 months to 3 years, depending on the material of the packaging bag and the contents inside.

Commonly we use mm (Millimeters), mil or Microns to describle film thickness.

1 mi l= 0.0254 mm

1 Micron = 1 um = 0.001 mm

And you may see PET12/PE90 in bag specification,

It means the bag is made of 12 Microns PET film and 90 Microns PE film

A three-side seal bag is a type of packaging where three sides are sealed, leaving one side open for the user to fill with the product. This is the most common method of bag manufacturing.

Aluminum Foil PET (VMPET) has both the characteristics of plastic film and metal. It can block light and prevent ultraviolet radiation, extends the shelf life of the contents, and improves the brightness of the film. It is also cheap, beautiful and has good barrier properties.

Aluminum Foil CPP (VMCPP) has good glossy, excellent light-shielding propert and can block gas and moisture.

Valve can be added on the packaging bag, It can prevent external air from entering the package and release the gas produced from contents.

The most common application is coffee packaging bag because coffee bean can generate CO2.

The zipper on the plastic packaging bag allows the bag to be reused after you open the bag.