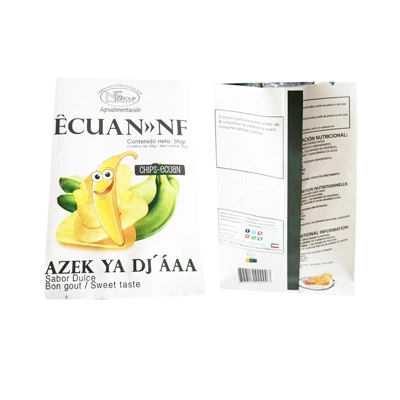

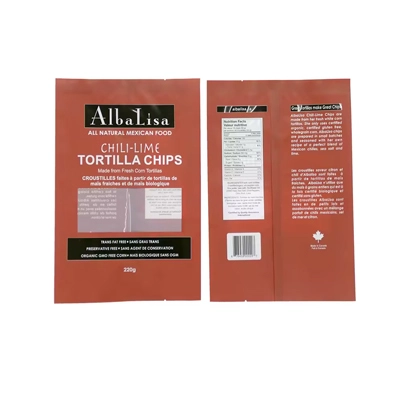

Premade back seal pouches are pre-manufactured bags that are filled with products and then heat-sealed at the top. This method is ideal for businesses looking for a straightforward, efficient packaging solution. Premade bags offer consistency in size and quality, making them perfect for small to medium-sized operations that require reliable and easy-to-use packaging options.

- Coffee Packaging Bags

- Baby Food Packaging Bags

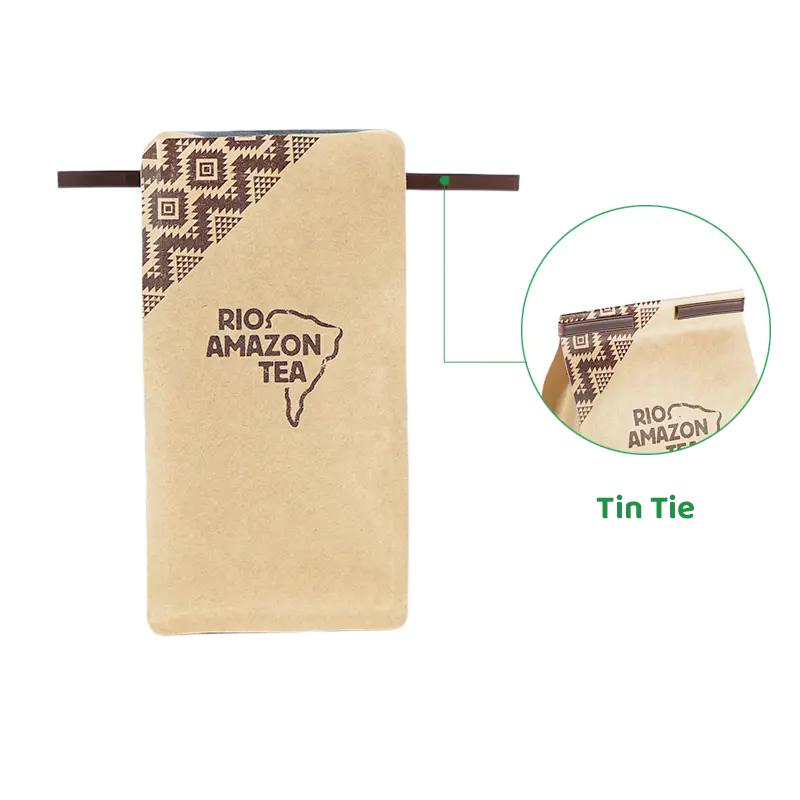

- Tea Packaging Bags

- Frozen Food Packaging Bags

- Protein Powder Packaging Bags

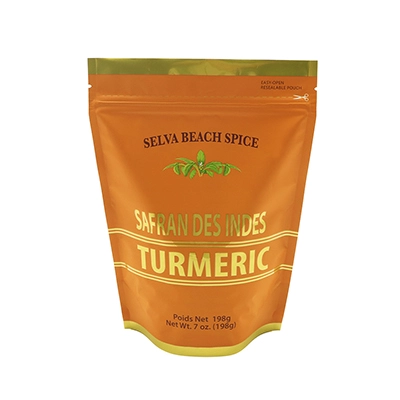

- Spice Packaging Bags

- Rice Packaging Bags

What are you looking for?