The outer base layer mainly plays the role of aesthetics, printing and moisture barrier such as BOPP, PET.

- Coffee Packaging Bags

- Baby Food Packaging Bags

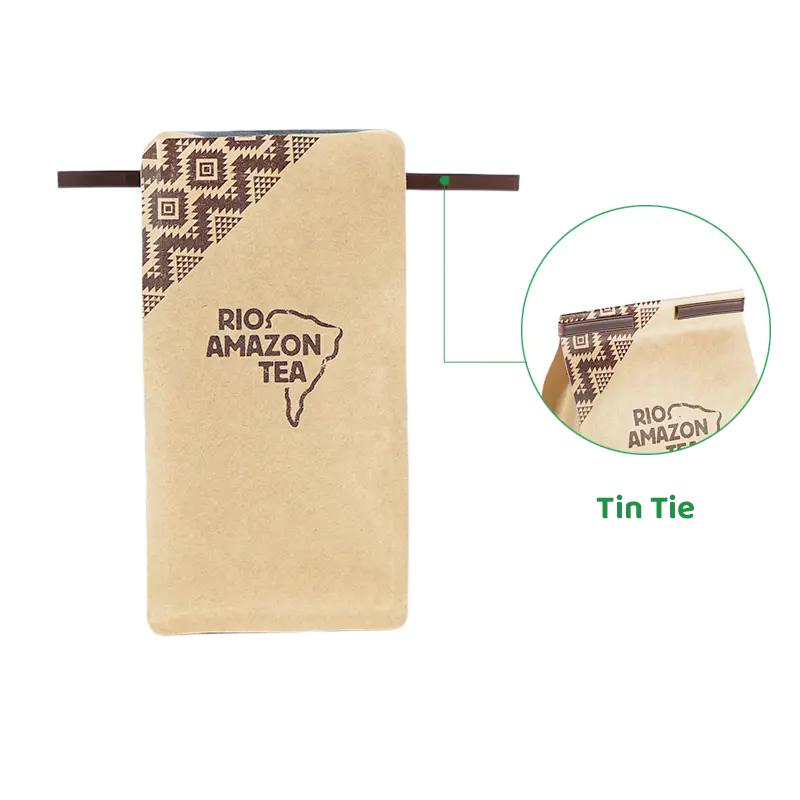

- Tea Packaging Bags

- Frozen Food Packaging Bags

- Protein Powder Packaging Bags

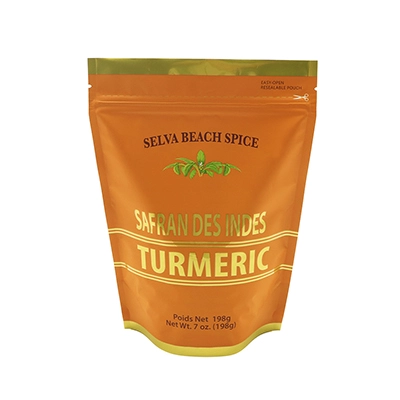

- Spice Packaging Bags

- Rice Packaging Bags

What are you looking for?