- Coffee Packaging Bags

- Baby Food Packaging Bags

- Tea Packaging Bags

- Frozen Food Packaging Bags

- Protein Powder Packaging Bags

- Spice Packaging Bags

- Rice Packaging Bags

What are you looking for?

In today's competitive market, the importance of customized packaging bags cannot be overstated. These bags not only protect the product but also serve as a powerful marketing tool that can attract consumers and boost sales.

Customized flexible packaging bags offer versatility, durability, and aesthetic appeal, making them a popular choice for many businesses.

This Blog gives a clear summary of all possible costs for custom printed packaging bags, helping you make smart choices and budget well.

The design of your packaging bag plays a crucial role in conveying your brand message and attracting consumers.

A well-designed bag can make your product stand out on the shelves and entice customers to make a purchase.Therefore, investing in a skilled and experienced designer is essential.

Some companies offer in-house design services, which can be convenient but may come with additional costs.

Design fees can vary widely depending on the complexity of the design and the designer’s expertise. On average, you can expect to pay anywhere from $100 to $500 for a professional design.

Remember, a compelling design is an investment that can significantly impact your product’s success.

Before placing a large order, it’s crucial to review samples to ensure the final product meets your expectations. There are several ways to obtain samples, each with its own cost implications.

The most cost-effective method is to request samples of similar bags previously produced by the supplier. However, if you need a sample based on your specific design, you will incur additional costs.

Digital print samples usually cost around $500 ( up to 100 pcs )

Gravure print samples,which offer higher quality, require a sample fee of about $300 and printing plate cost ( about $100 per plate)

Cromalin samples, used to check color and print quality, are usually free.

Don't forget the shipping costs for the samples, which generally range from $30 to $50.

The style of the bag is a significant determinant. For instance, flat bottom bags are more expensive than gusset bags, stand-up pouches, shaped bags, back-seal bags, and flat bags.

The choice of bag material will influence price. Bags made from PET/VMPET/PE are generally cheaper than those made from PET/AL/PE.

Thicker bags (e.g., 130 microns) and multi-layered bags (e.g., four layers) are more expensive due to their enhanced barrier properties.

The size of the bag is another crucial factor, as larger bags consume more raw materials. For example, a 500g coffee bag will cost more than a 250g coffee bag.

Additional features like zippers, valves, handles, spouts, and special processes such as spot UV, holographic film, and hot stamping can further increase the cost.

Order quantity will influence bag price. Bigger orders usually mean lower costs per item. The minimum order quantity is usually around 10,000 pieces.

Printing plates are essential for transferring your design onto the packaging material. The cost of each printing plate ranges from $70 to $150, depending on the complexity of the design.

The number of plates required is determined by the number of colors used in your design. For instance, a simple three-side seal bag using basic CMYKW colors will need five plates.

If your design includes special colors (spot colors), you will need additional plates for each color. The maximum number of colors supported by most printing machines is ten.

Understanding these costs is crucial for budgeting and ensuring your design is accurately reproduced.

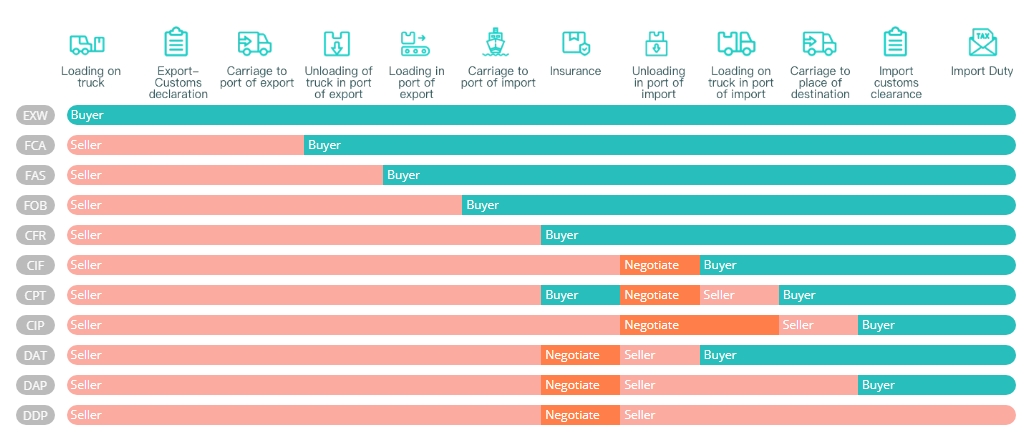

When dealing with international suppliers, it’s important to consider shipping costs. These costs can vary based on the shipping terms agreed upon.

FOB (Free On Board) means the seller delivers the goods to the port, and then the buyer takes over responsibility.

CIF (Cost, Insurance, and Freight) includes the cost of goods, insurance, and freight to the destination port.

DDP (Delivered Duty Paid) covers all costs, including delivery to the buyer’s location.

Understanding these terms and their cost implications is essential for accurate budgeting and avoiding unexpected expenses.

In summary, the cost of customized flexible packaging bags is influenced by several factors, including design fees, sample fees, bag style, material, size, additional features, printing plate fees, and international shipping costs.

By understanding these costs, you can make informed decisions and effectively budget for your packaging needs. Customized packaging is an investment that can significantly impact your product’s success, so it’s essential to consider all these factors carefully.

1.What are the main factors that influence the cost of customized flexible packaging bags?

The main factors include bag style, material type, thickness, number of layers, bag size, additional features. For instance, back seal pouches and bath salt packaging bags may vary in cost depending on these factors.

2.How can I reduce the cost of my packaging design?

You can reduce design costs by opting for simpler designs, using fewer colors, and working with experienced designers.

3.What are the different types of samples available?

The types of samples include digital print samples ,gravure print samples and Cromalin samples.

4.What's DDP means?

DDP covers all costs, including delivery to the buyer’s location.

5.Why do I need to pay for printing plates?

Printing plates are necessary for transferring your design onto the packaging material.